Dubai’s manufacturing sector sits at the crossroads of innovation, sustainability, and economic diversification. As global supply chains strain under resource scarcity, rising costs, and environmental pressures, traditional “take‑make‑dispose” industrial models are showing their limitations. The circular economy offers an alternative path that aligns industrial performance with sustainability goals while opening fresh avenues for competitiveness, investment, and job creation.

Under the UAE Circular Economy Policy 2021–2031, the government has put circular principles front and center, aiming to shift manufacturing toward resource efficiency, recycling, reuse, and smart design that keeps products and materials in productive use longer. This policy spans 22 critical initiatives across manufacturing, infrastructure, food systems, and transportation, setting a national roadmap for sustainable economic transformation.

For Dubai’s manufacturers, this shift is a transformational opportunity. By adopting circular practices, companies can reduce dependence on imported raw materials, lower production costs, mitigate waste, and unlock new revenue streams from remanufacturing, refurbishment, and recycled materials. In a city focused on innovation and global competitiveness, circular economy principles make sustainability a strategic asset rather than a compliance cost.

What is Circular Economy?

At its core, the circular economy is a system designed to eliminate waste and continually use resources. Unlike the traditional linear economy, where products are made, used, and discarded, the circular model focuses on closing loops through strategies like recycling, reusing, and remanufacturing. This creates a regenerative cycle that benefits the environment, economy, and society.

In practice, this means designing products with their end-of-life in mind, so materials can be recovered and reintegrated into production. For instance, instead of sending scrap metal to landfills, manufacturers might repurpose it into new components. The Ellen MacArthur Foundation, a leading advocate for circular principles, estimates that globally, this approach could generate $4.5 trillion in economic benefits by 2030 through reduced material costs and new business models.

For Dubai, adopting a circular economy aligns perfectly with its vision of becoming a global hub for sustainable innovation. The city's strategic location as a trade nexus amplifies these benefits, allowing manufacturers to export eco-friendly products to international markets. Moreover, it addresses local challenges like water scarcity and high energy consumption. By shifting to circular practices, businesses can cut down on raw material imports, which are costly in a desert environment, and instead rely on local recycling networks.

This model also promotes collaboration across industries. In eco-industrial parks, one company's waste becomes another's input, fostering symbiosis. The UAE's policy emphasizes this, encouraging private sector involvement in cleaner production methods, including the use of artificial intelligence for optimizing resource flows. As Dubai integrates these ideas, manufacturers will find themselves not just complying with regulations but thriving in a market that values sustainability.

Government Policy and Support for Circular Manufacturing

The UAE Circular Economy Policy 2021–2031 provides a comprehensive framework for circular practices in manufacturing and beyond. This policy encourages sustainable remanufacturing, resource productivity improvements, and circular design across industries.

The national roadmap includes:

- Regulatory incentives for circular business practices.

- Support for waste‑to‑resource infrastructure.

- Collaboration between public and private sectors.

- Tracking and reporting systems for material flows.

This supportive environment lowers barriers to adoption and accelerates circular transformation for Dubai manufacturers.

Key Circular Economy Opportunities in Dubai’s Manufacturing Sector

1. Resource Efficiency and Waste Reduction

Manufacturers that integrate resource‑efficient processes can significantly lower production costs. This includes:

- Process optimisation to cut material loss and energy use.

- Lean production techniques that reduce inputs without sacrificing output quality.

- Waste‑to‑resource systems where by‑products become feedstock for new products.

Dubai’s policies encourage a move away from the linear model toward strategies that reuse, recycle, recover, or redesign products and processes.

2. Remanufacturing and Refurbishment

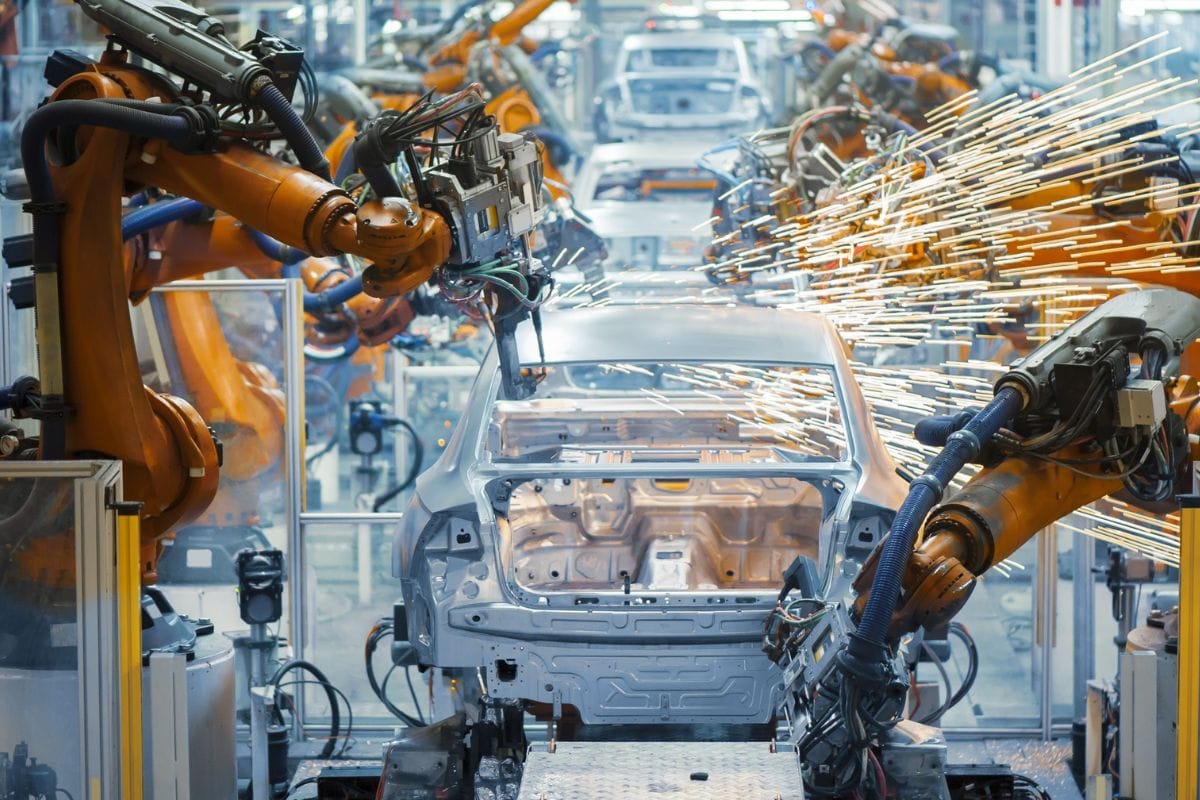

Remanufacturing extends product lifecycles by restoring used components to like‑new condition. This creates value while lowering demand for raw materials and reducing energy consumption. For example, in the automotive sector, roughly 86 percent of a vehicle’s materials can be recycled or remanufactured, highlighting a clear opportunity for parts manufacturers and service providers.

Benefits of remanufacturing for Dubai manufacturers:

- Reduced material costs.

- New revenue streams from secondary markets.

- Enhanced brand reputation in sustainability.

3. Recycling and Material Recovery

Even with resource efficiency and remanufacturing, some waste remains. Advanced recycling technologies allow manufacturers to reclaim valuable materials that would otherwise be lost. In the UAE and across the GCC, initiatives such as aluminium recycling ecosystems showcase how industrial players can collaborate to create circular value chains.

Recycling creates commercial opportunities in:

- Plastic and metal recovery.

- Textile and composite material recycling.

- Electronic waste processing.

These activities not only support sustainability goals but also attract investment and innovation in high‑value recycling technologies.

4. Circular Product Design and Innovation

Redesigning products to be repairable, modular, or recyclable from the outset adds long‑term value. Manufacturers that lead in circular design gain a competitive edge by offering products that are cheaper to maintain, easier to upgrade, and more appealing to sustainability‑conscious consumers.

Key design strategies include:

- Modular components for easy repair and upgrade.

- Use of recyclable or bio‑based materials.

- Designs that simplify disassembly at end of life.

These approaches align manufacturing with evolving global demand for sustainable products.

5. Digital Technologies That Enable Circularity

Digital tools play an essential role in tracking material flows, optimising processes, and enabling new business models. For manufacturers eager to scale circular practices, technologies such as:

- Internet of Things (IoT) to monitor resource use.

- Blockchain for transparent supply chains.

- Artificial intelligence to predict maintenance and optimise logistics.

While academic research underscores the need for wider adoption and integration of these technologies, the potential for efficiency gains and circular transformation is clear.

6. New Business Models and Revenue Streams

Incorporating circular principles enables manufacturers to pivot toward innovative business models:

Product‑as‑Service (PaaS):

Manufacturers retain ownership of products and offer them as services. This incentivises designs that last longer and can be reused.

Take‑back and Return Schemes:

Incentivising customers to return end‑of‑life products creates feedstock for remanufacturing or recycling.

Upcycling and Secondary Markets:

Transforming used products into higher‑value offerings strengthens brand differentiation and unlocks new markets.

These models strengthen customer relationships while embedding sustainability directly into business strategy.

Challenges in Transitioning to Circular Models

While promising, the shift to a circular economy in Dubai's manufacturing isn't without obstacles. High initial costs for technology upgrades, like AI systems or recycling infrastructure, pose a barrier for small and medium enterprises. Training workers for new skills requires investment, and supply chain complexities can hinder material recovery.

Regulatory gaps also exist; although the UAE policy provides a framework, enforcement varies across emirates. Data scarcity on resource flows makes planning difficult, as noted in symbiosis studies for UAE industries (ScienceDirect). Environmental challenges, such as Dubai's arid climate, complicate water-intensive recycling processes.

Market demand for circular products is growing but inconsistent, with consumers sometimes prioritizing cost over sustainability. Global supply disruptions, like those in raw materials, exacerbate vulnerabilities.

Solutions are emerging. Government subsidies and partnerships, as in the Circular Economy Council, ease financial burdens. Capacity building through workshops, per the UAE policy, addresses skills gaps. Collaborative networks in industrial zones foster knowledge sharing. By leveraging Dubai's innovation ecosystem, including free zones, manufacturers can pilot projects and scale successes. Overcoming these challenges will require stakeholder alignment, turning potential pitfalls into stepping stones for growth.

Circular economy principles are reshaping how manufacturing will compete and grow in the decades ahead. For Dubai’s manufacturing players, this transformation aligns economic performance with sustainability goals, reducing waste, improving resource efficiency, and unlocking new market opportunities. With strong government backing, supportive policies, and growing global demand for sustainable products, the emirate has a unique chance to become a regional and global leader in circular manufacturing.

Manufacturers that embrace circular models now will not only reduce environmental risk but also position themselves for future‑ready growth that resonates with investors, customers, and the broader economy.

Also Read: