Global technology company, OPPO, has revealed that all its smartphones are subjected to more than 150 quality engineering tests at the company’s state-of-the art Quality Engineering (QE) Lab, before each model goes into mass production. Recognising consumers’ emphasis on high product quality in their choice of smartphones, OPPO’s rigorous testing process involves over 1.1 million actions performed on each phone model, demonstrating the company’s unrelenting commitment to product quality.

OPPO has pioneered several testing categories that cover a wide range of usage scenarios and customer groups to ensure that consumers receive nothing but the best. The QE Lab’s 150 device tests include new material certifications, quality compliance, routine product monitoring and others, ensuring that each smartphone meets the highest standards of quality and reliability. Quality monitoring continues throughout the product life cycle, from early development stage to mass production, with sample inspections conducted by the QE Lab.

Commenting on that, Tarek Zaki, Senior Product Manager at OPPO MEA, said,

“We understand our customers acknowledge the importance that they place on product quality. This is why we adopt stricter testing standards than the industry norms, staying true to our belief in human-centric innovation. The OPPO QE Lab leaves no stone unturned to ensure that our smartphone deliver a flawless experience, undertaking more than 150 tests and over a million actions on each smartphone model. We are continuously striving to bring the benefits of technology to people, while leaving all the complexity to ourselves.”

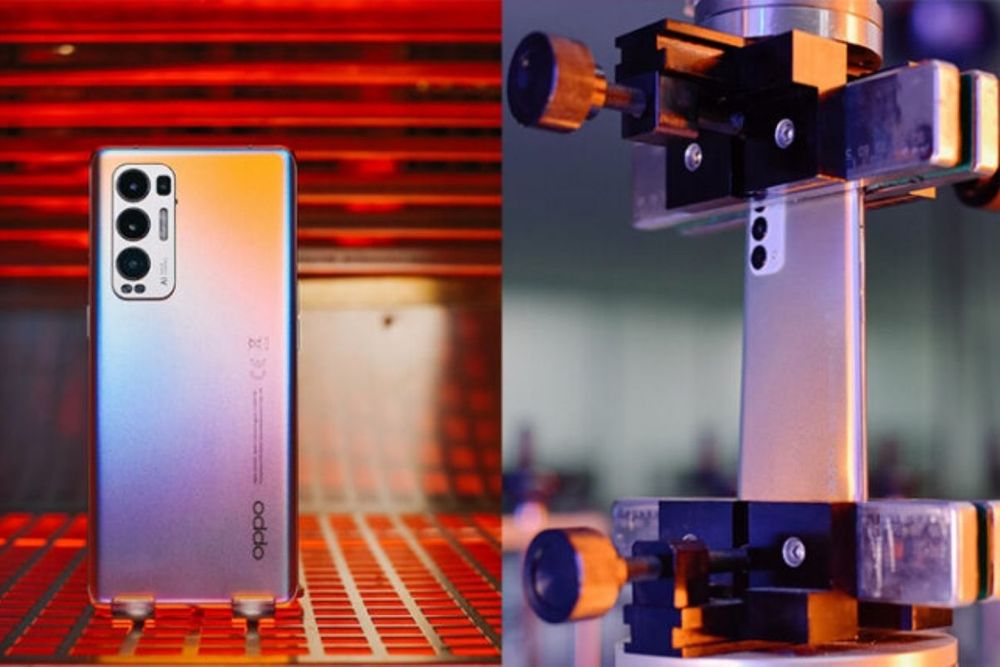

OPPO’s quality tests have been designed to reflect the actual consumer experience, so that common but overlooked motions such as USB plug-in and plug-out, and slight drops are not missed. OPPO also released a video for consumers to witness the testing process in motion at the QE Lab as the phones are perfected to meet and exceed customer expectations. The tests featured in the video are a select few tests from the complete range, including:

- Drop test: This test involves raising the device to a certain height (up to 1.8m) and then allowing it to fall freely onto a marble surface from different angles. This checks for failure to function, cracking of the outer shell and detachments of any components.

- Button click test: As the power and volume keys are most frequently used, each button is tapped 100,000 times, and the fingerprint key is tapped 1 million times. This ensures that the keys are comfortable to touch, functional and intact.

- Plugging test: Users insert and withdraw the USB frequently to charge the device and play music. In this test, the USB is inserted and withdrawn 10,000 times either manually from different angles or by applying different insertion and withdrawal force. This test checks the life of the USB and headphone jack, and is designed to detect functional failure or poor contact.

- Twisting test: A user may twist the device in use, thus damage it. To verify this, the twisting test is conducted 1,000 times using torque calculated based on the width and depth of the device. This test checks for structural or functional damage. After the test, the device is disassembled to detect any signs of internal structural damage.

- Press test of the whole device: This test simulates a scenario where the user accidentally presses the device against a small pointed object (such as a key or flash drive in a pocket) and verifies whether the device is damaged or functionality is affected.

- Rain test: To test the daily waterproof performance of the device, this test simulates using the device on moderate rainy days. During the test, the device is powered on, while being pitched with water spray from different angles. The device is then set aside for three days to ensure that the water inside the device evaporates and disassembled to verify that the main PCB interface and display screen are not corroded.

- Salt spray test: This test simulates a coastal area where the air is humid and contains a high proportion of salt. The test aims to verify whether moisture that infiltrates the device corrodes the internal components and other metal parts, causing function failure.

- Environment aging test: This test checks how the phone ages when stored in a simulated environment created for usage under extreme weather conditions.

- Friction test: This test uses special sandpaper to rub the case back and forth 2,000 times to test the durability of the phone case.

To maintain one of the highest industry quality standards, OPPO has more than 85% of its devices’ components developed within the company’s own factories. Apart from the quality tests conducted in the QE Lab, each OPPO smartphone that are commercially ready for sales eventually undergoes over 390 tests in total before it leaves the factory.

OPPO continues to push the boundaries of quality and design, delivering a human-centric experience that surpasses customer expectations and empowers users to elevate their lives through technology. For more information, visit www.oppo.com/ae.

Canonical Link: https://www.bizbahrain.com/oppo-smartphones-undergo-more-than-150-rigorous-quality-engineering-tests-over-1-1-million-actions/

© Copyright 2021 bizbahrain